|

|

PIONIER4000

PIONIER4000 - Precision profile bar machining centre of very high quality for machining profiles made of steel and stainless steel, aluminium - non-ferrous metals + plastics, the machine is an encapsulated production island with automatic front door - hardly any noise and chips in the hall, four fully-fledged CNC axes, CNC control with touch screen and 3D colour graphics - CAD/CAM software with 3D simulation, maximum machining length 4,000 mm (with feed 8. 000 mm) - automatic three-sided machining in one clamping, largest profile cross-section 200 mm x H 200 mm, electric motorised swivelling work table +/- 90° stepless, can be combined with a sawing unit for sawing profiles up to 80 mm high, milling spindle drive power 6.6 kW - milling spindle speeds up to 18. 000 rpm - covered tool magazine for 10 tools - HSK63 tool holder - automatic tool length measurement, YASKAWA® drive motors and drive controller - rapid traverse speeds up to 50 m/min, central lubrication system, spray mist coolant system plus flood coolant system for stainless steel processing, space requirement approx. 5 m x 2,1 m H 2,1 m, weight approx. 3.500 kg. |

|

|

|

Our PIONIER4000 profile bar processing centre enables fully automatic three-sided processing of the profile bar, the profile is swivelled to the desired angle by a CNC-controlled tilting table, table swivel range 180° stepless. |

|

|

100% designed and built in EUROPA

90% built from European components* for efficient, environmentally friendly production of the highest quality. *European components mean short transport routes, very high quality and extensive availability. |

|

|

|

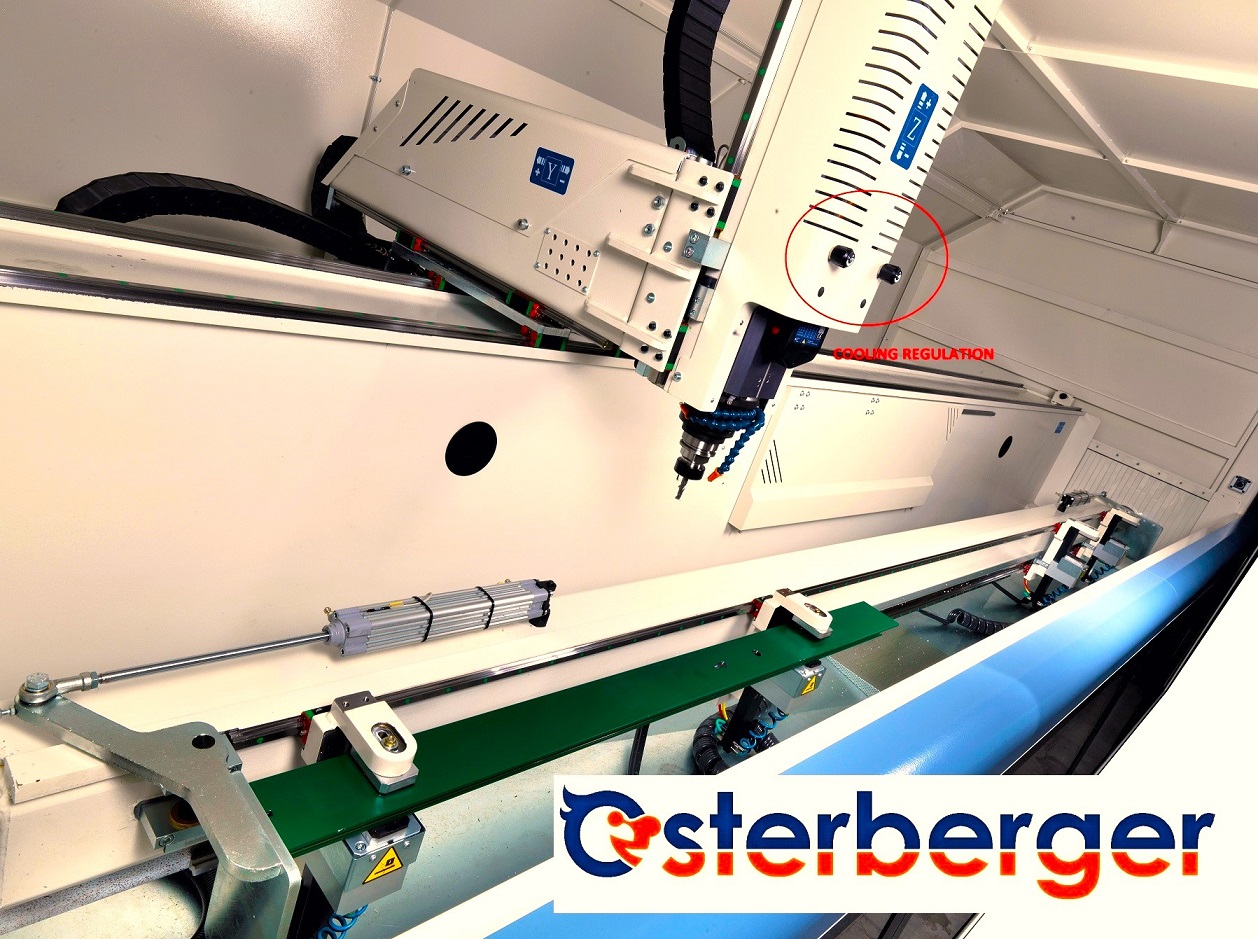

The Pionier4000 profile bar machining centre with 6.6 kW milling spindle drive power can also machine steel and stainless steel profiles by drilling, tapping and milling thanks to its rigid, heavy structure and the large linear guides of the X/Y/Z axes.

Two systems are installed for the cooling lubrication of the tools, a classic flood cooling system and a spray mist minimum lubrication system. |

|

|

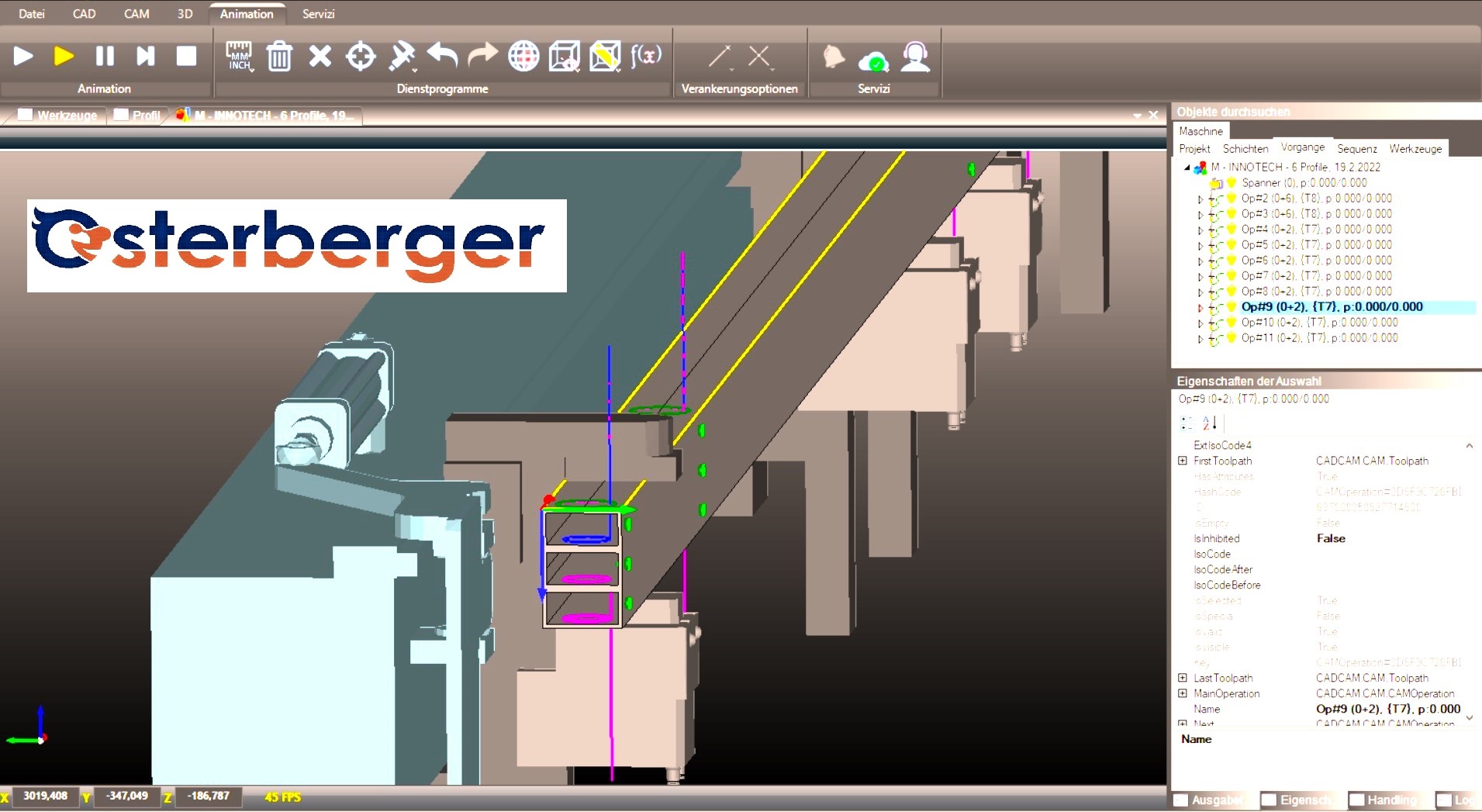

Our software is a 3D software with colour graphics. The uncomplicated and very simple workpiece programming can be carried out in the office or directly at the machine. Tools are managed in a tool library. All workpieces/profiles can be saved and managed as DXF or STEP files. |

|

|

Our PIONIER4000 can also be equipped with a sawing unit on request, allowing aluminium tubes and profiles up to 80 mm high to be processed by saw cutting. |

|

|

MADE IN EU - also means short transport routes. The systems, equipment, machines and devices we offer do not have to be transported thousands of kilometres by sea. Everyone talks about environmental protection and resource conservation, we act accordingly and pay attention to sustainability. We make sure that the systems, equipment, machines and devices we sell are manufactured with the lowest possible environmental impact and the greatest possible conservation of resources.

|