|

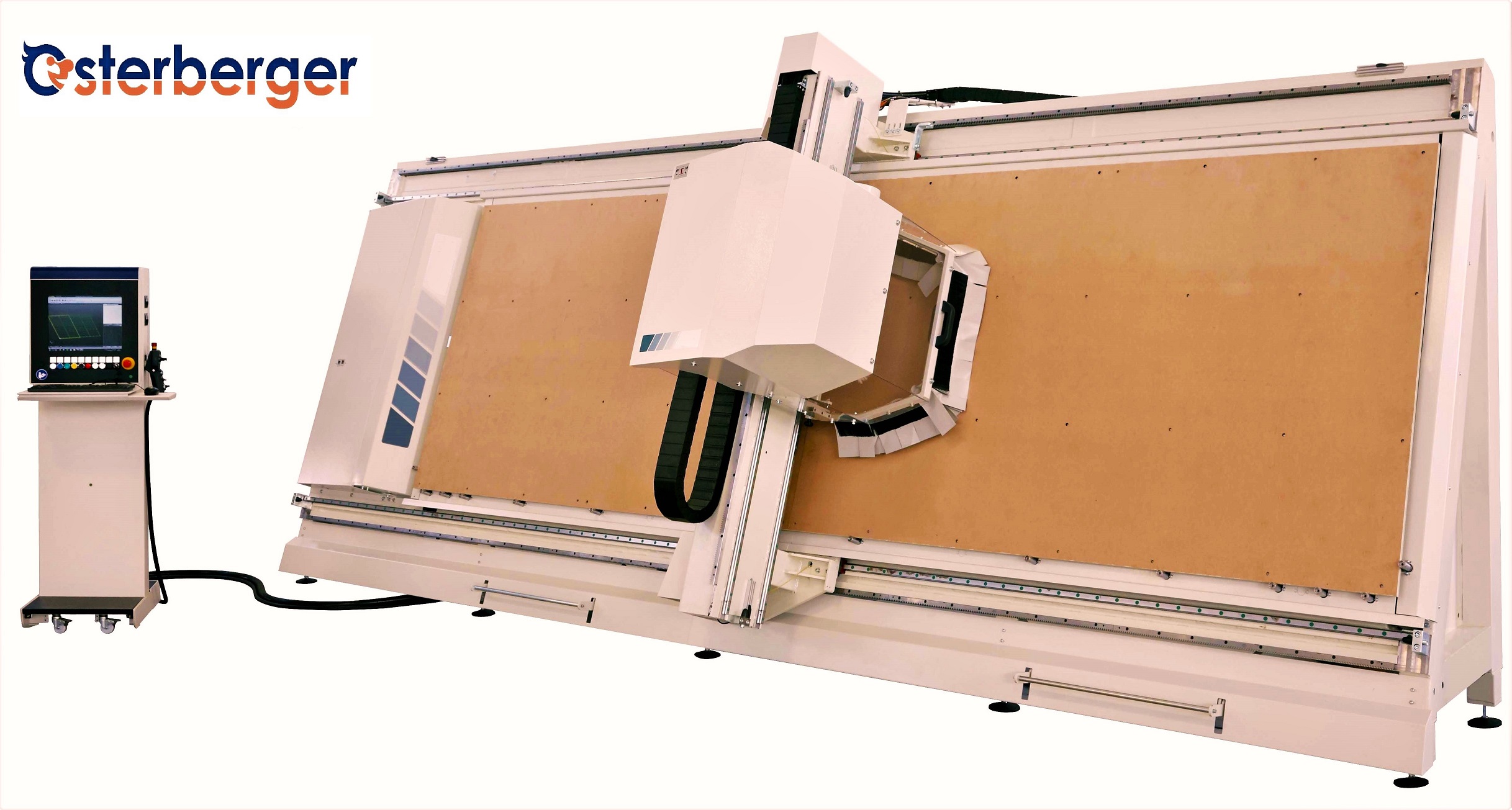

OSTERBERGER panel and board processing centre STBZ1600Nesting

Drilling + Milling + Sawing + Brushing + Grinding + Polishing

|

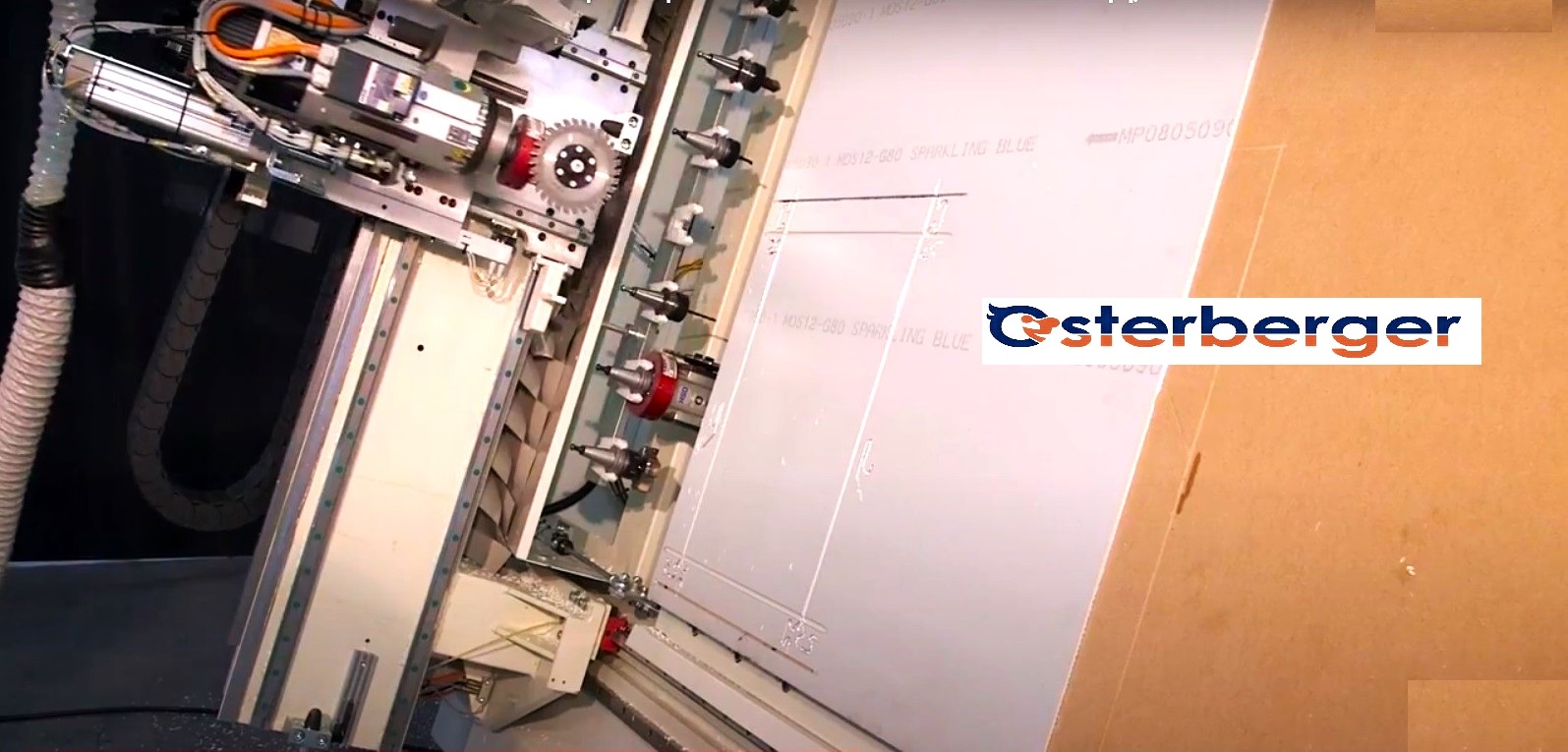

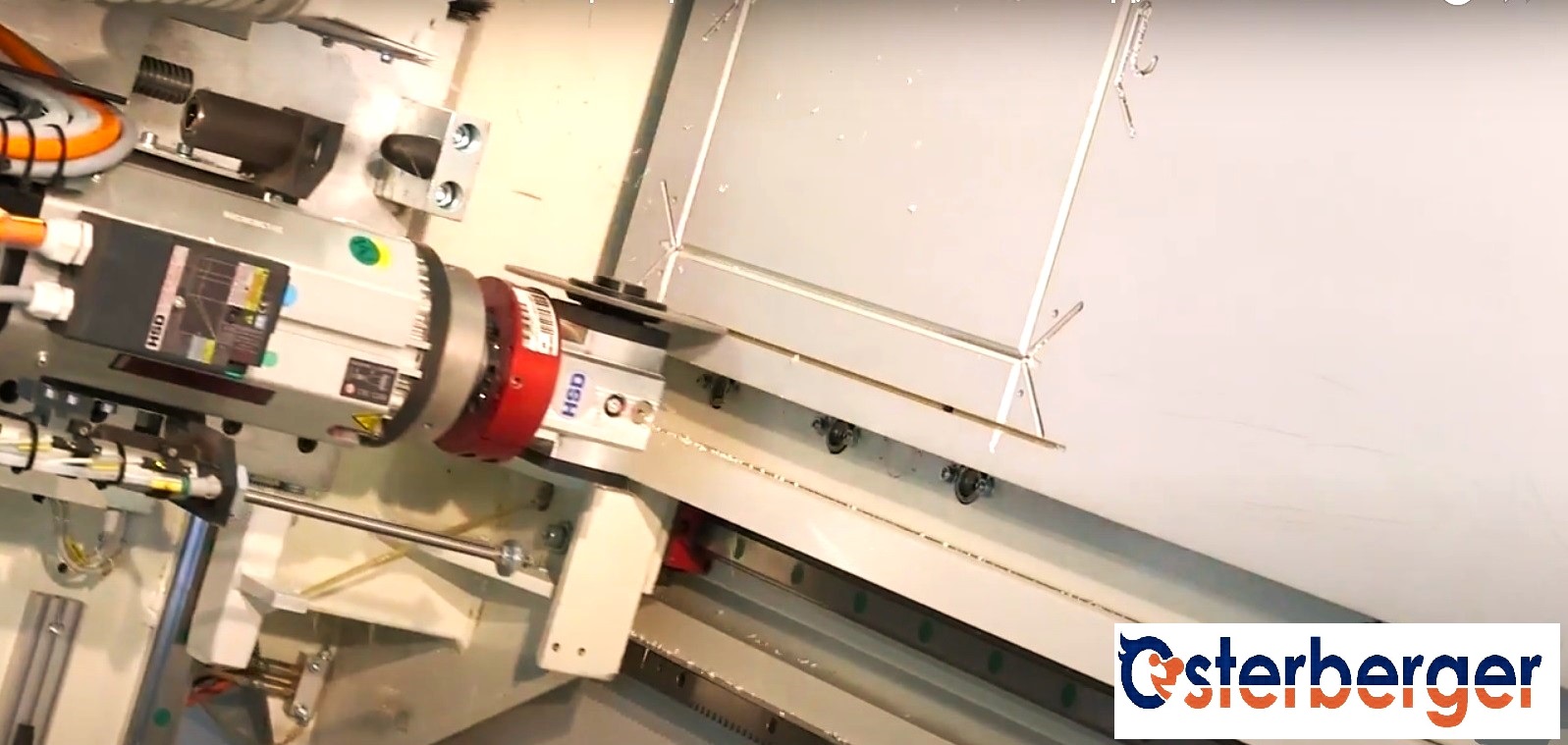

OSTERBERGER multifunctional panel and board processing centre STBZ1600Nesting - two CNC machines integrated into one compact multifunctional machine - designed to produce ventilated rainscreen cladding - for prefabrication in drywall and acoustic construction, for aluminium and wood panel processing. Sawing + drilling + milling (also V - groove routing with a separate routing unit) + brushing + sanding + polishing, all with a single multifunctional machine.

|

CNC - controlled very compact multifunctional inclined table machining centre with low space requirement - for the machining of plates and panels made of all (easily) machinable materials such as e.g. Aluminium plates and aluminium sheets, non-ferrous metal plates and non-ferrous metal sheets, composite materials - such as Alucobond® - Reynobond® - Dibond® and others, fibre cement boards - such as Eternit®, synthetic resin boards - such as Fundermax®, HPL laminates, melamine resin boards such as Trespa® - Meteon® - Senoplan®, solid surface materials such as Corian®, plasterboard, mineral fibre boards such as Fermacell®.

|

The workpiece is attached to retractable stops and clamped with a vacuum. Machining area optionally 3,000 mm, 5,000 mm, or 7,000 mm (the machines are available with a machining length of up to 14 m) x 1,600 mm (optional 2. 000 mm) x H 25 mm, routing spindle drive power 7.5 kW - SK 30 tool holder - covered tool magazine for 8 vertical tools and two sawing units (for automatic panel and panel dividing in vertical and horizontal direction), - separate horizontal routing unit (swivelling via the CNC) for disc form cutters up to Ø150 mm diameter for V-groove operations in composite panels and plasterboard, maximum workpiece height when sawing 20 mm, very compact dimensions - with a small footprint of only 1.7 m x H 2.45 m, workpieces up to a length of 3 m, 5 m or 7 m and a width of 1.6 m can be processed by drilling - milling - sawing - sanding - brushing - polishing, weight of the machine approx. 4. 500 kg.

|

|

|

|