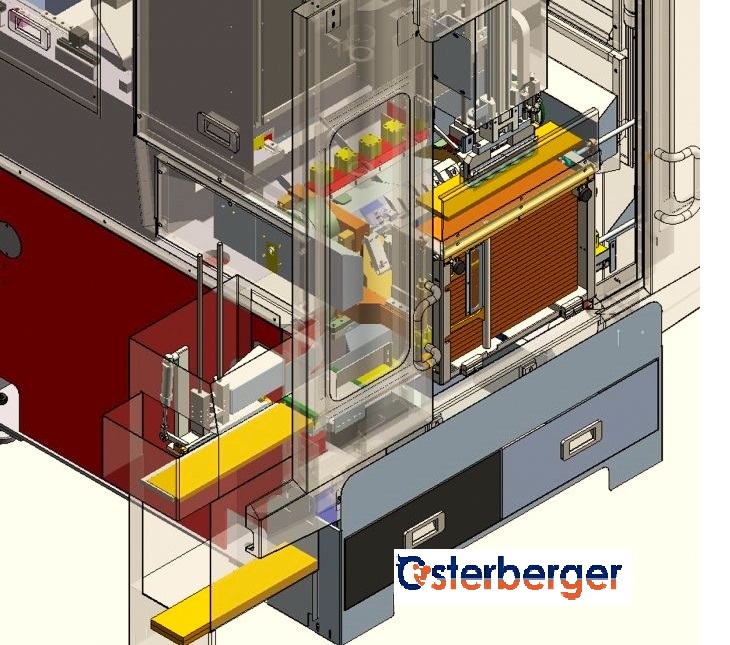

ORNAMENTUM500.3HSC - High Speed Cutting- Nano- Special machining centre

|

ORNAMENTUM500.3HSC – High- Speed Cutting special machining centre with FANUC® nano contouring technology for the fashion accessory or jewellery industry and similar industrial processing where the highest possible precision is required, such as dental technology - medical technology - mould making. For the machining of precious metal alloys as well as aluminium - copper - brass - bronze and similar non-ferrous metals, the starting material to be machined are forged - cast or rolled flat bars up to 150 mm wide and a maximum length of 500 mm which are stored in a blank magazine. Automatic loading of the flat bars (starting or raw material), material thickness 1 mm to 15 mm - automatic unloading of the finished flat bars. Milling spindle drive power 8 kW - Milling spindle speeds up to 36. 000 rpm - HSK40 tool holder - tool magazine for 24 tools, automatic pneumatic flat bar clamping - automatic table rotation through 180° with the clamped raw material for fully automatic back working in a single clamping operation, axis positioning accuracy better than +/- 0, 01 mm (depending on ambient conditions), FANUC® three-axis CNC 3D control with special software for demanding ornamental milling work, FANUC® axis drives, FANUC® milling spindle drive - liquid-cooled milling spindle, automatic central lubrication system, dimensions approx. 3.5 x 2.6 m x H 2.9 m, weight approx. 3. 000 kg.

|