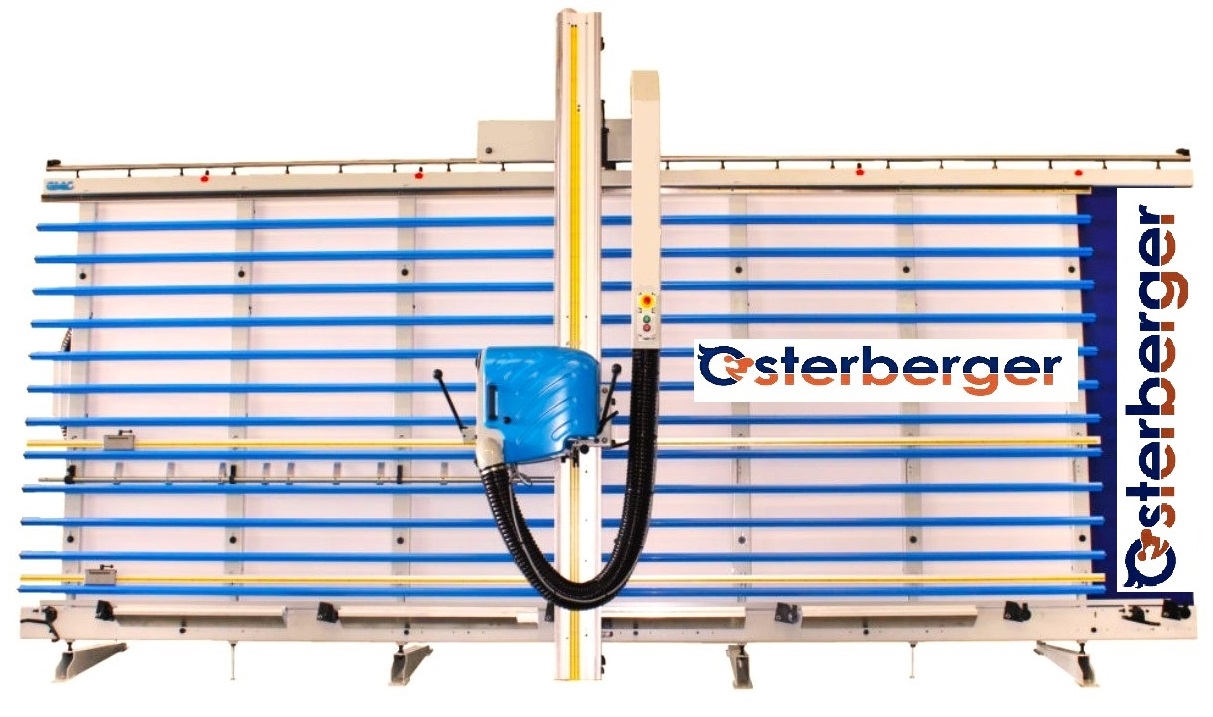

VPS-RSF250.3M - manual vertical panel sawing machine

|

OSTERBERGER VPS-RSF250.3M - vertical circular sawing machine for manual cutting of panel materials - we also supply the machine programme-controlled for automatic cutting - brand new.

|

All easily machinable materials such as solid wood panels / glued wood panels / shuttering panels and all wood-like materials such as MDF - fibreboard - pressboard can be cut and divided by sawing. However, depending on the configuration of the machine, panels made of aluminium, non-ferrous metals, plastics such as PVC - acrylic glass, composite materials such as Alucobond® / Reynobond®, plasterboard, Corian®, Fermacell®, Fundermax®, fibre cement panels such as Eternit® and HPL panels can also be cut / sawn.

|

|

|

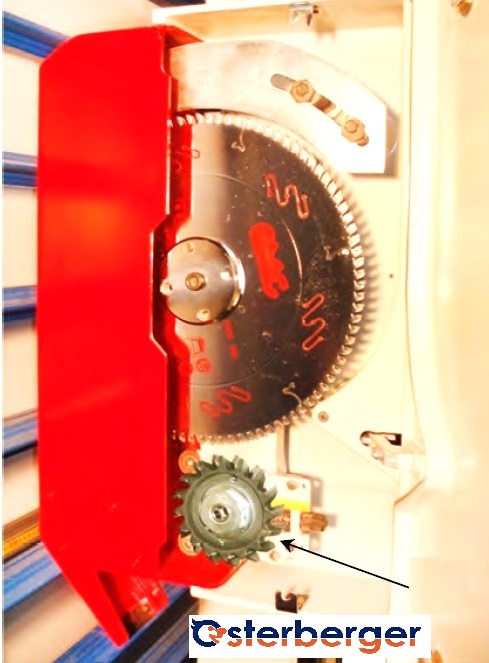

"V - Groove" - "V - Milling" in composite materials such as Alucobond® / Reynobond® and in plasterboard can be carried out with our vertical circular sawing machine VPS-RSF250.3M with the milling unit equipment. Two V - Groove cutters (disc cutters) can also be clamped next to each other on the routing unit shaft. With the routing unit equipment, it is possible to produce corner panelling - wall finishes - U and Z - shaped workpieces and similar products. We supply V-milling tools as disc cutters with 90° and 135° milling angles and tools with other milling angles.

|

Maximum cutting range 3,200 mm x height 1,900 mm or 4,200 mm x height 2,200 mm, maximum horizontal cutting height 1,650 mm or 2. 070 mm - the saw unit is rotated manually (or automatically under programme control in the NC-controlled version), the maximum panel thickness that can be cut through is 60 mm, drive power saw motor 3 kW (optionally 4.5 kW) - saw blade diameter 250 mm, compressed air pressure requirement 7 to 8 bar, dimensions approx. 4,300 / 5,300 mm x 1,500 x H 2,580 / 2,690 mm, weight approx. 590 / 690 kg.

|