|

Universal BRIDGE SAWING CENTRE Model BSM5.3500CNC

|

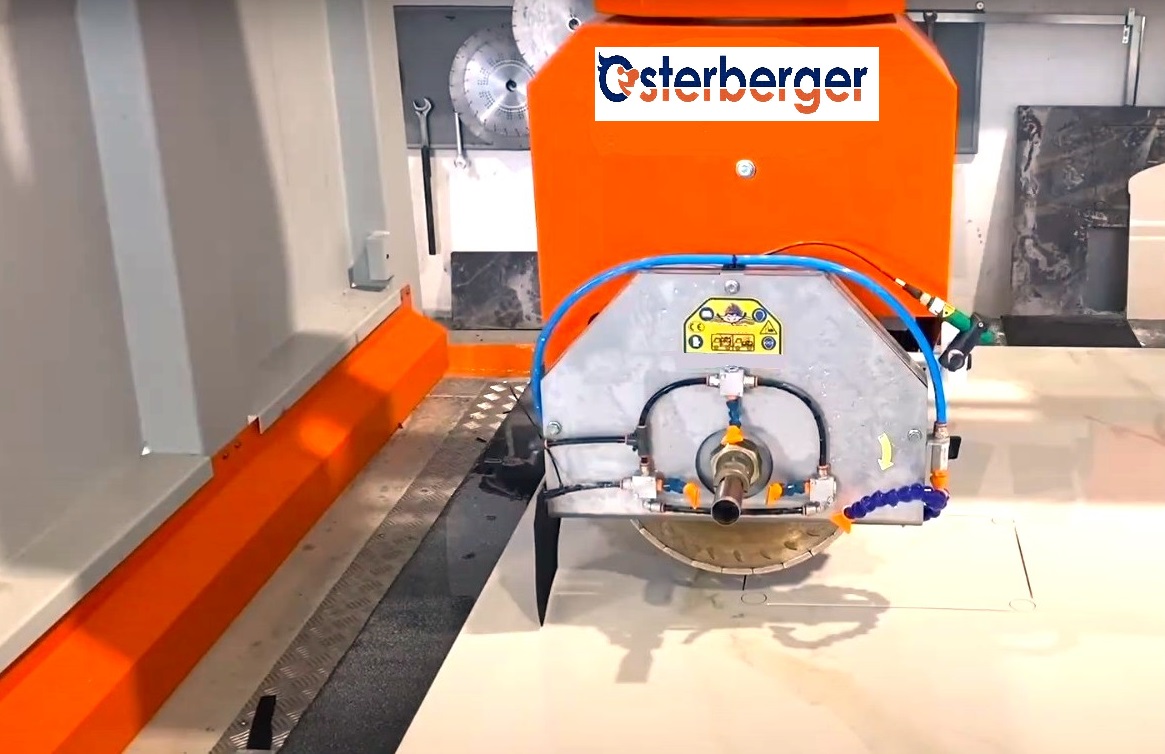

OSTERBERGER compact bridge sawing machine with five CNC-controlled axes - model BSM5.3500CNC. A universal processing centre for processing natural stone, for example granite, marble, travertine, and basalt - artificial stone - ceramic slabs, with five CNC-controlled axes - sawing / drilling / milling / grinding and polishing with a single machine.

|

CNC control with 15" touchscreen and colour display, the five interpolating axes allow complex processing. Many software tools are included in the scope of delivery for quick and easy programming (so-called "macros", i.e. pre-programmed machining programmes) of - longitudinal and cross cuts - 45° bevel cuts - circular cuts - elliptical cuts - curved cuts - software for drilling holes - special software for machining kitchen worktops - special software for machining ceramics (tiles + slabs) - special software for engraving work. Remote control console for controlling manual movements, for measuring raw panels, for manual work with the machine. CAM software for reading and generating DXF files is available as an option.

|

The machine is equipped with a line laser (green line beam), which makes it possible to recognise marked points and saw along the markings in manual mode using the mobile remote control.

|

Our BSM5.3500CNC bridge sawing machine has a table size of 3,500 mm x 2,100 mm and a working area of 3,500 mm x 1,900 mm for 90° processing by sawing and routing. The support table is equipped with a 40 mm thick rubber plate, and the machine can also be loaded vertically with panel material thanks to the hydraulically swivelling support table. A hydraulic panel lifting device with rollers for easy movement of the workpieces to be processed is available as an option.

|

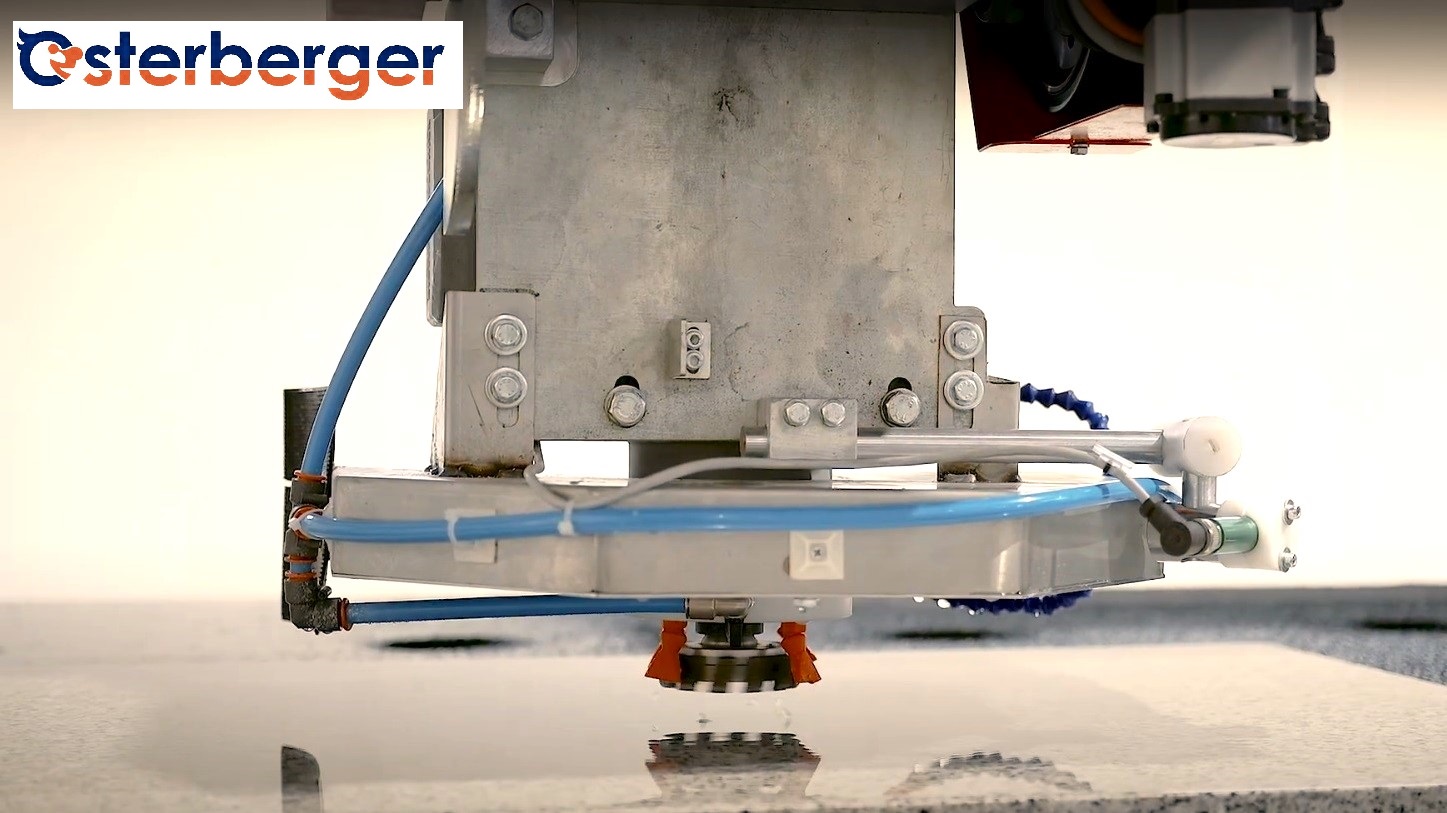

Largest saw blade diameter Ø 450 mm - saw blade drive power 15 kW - saw blade speeds 600 to 6,000 rpm infinitely programmable - maximum cutting thickness 140 mm - automatic saw blade diameter measurement. Optionally available with flood cooling system and cooling water treatment system, the machine can also be supplied with a complete enclosure. Machine dimensions 5.9 x 2.3 x H 2.51 m, machine weight 3,200 kg.

|

|

|

The X/Y and Z axes slide on hardened and ground linear guides. These guides are protected from dust and cooling water in the X and Y axes by bellows.