|

REPANDUS - R70CNC.Ku - Profile bending machine for plastic profiles

|

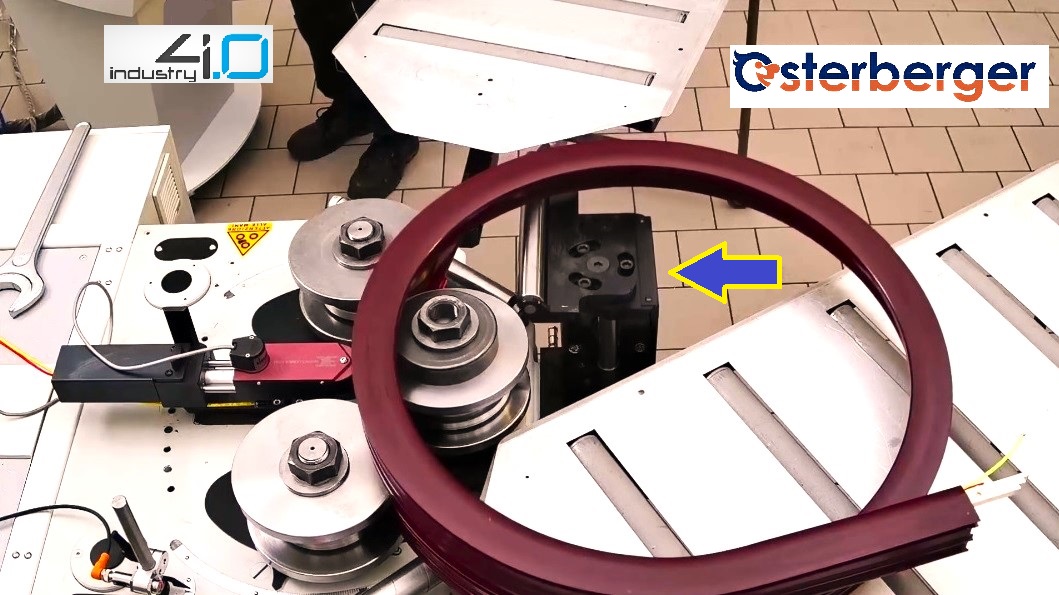

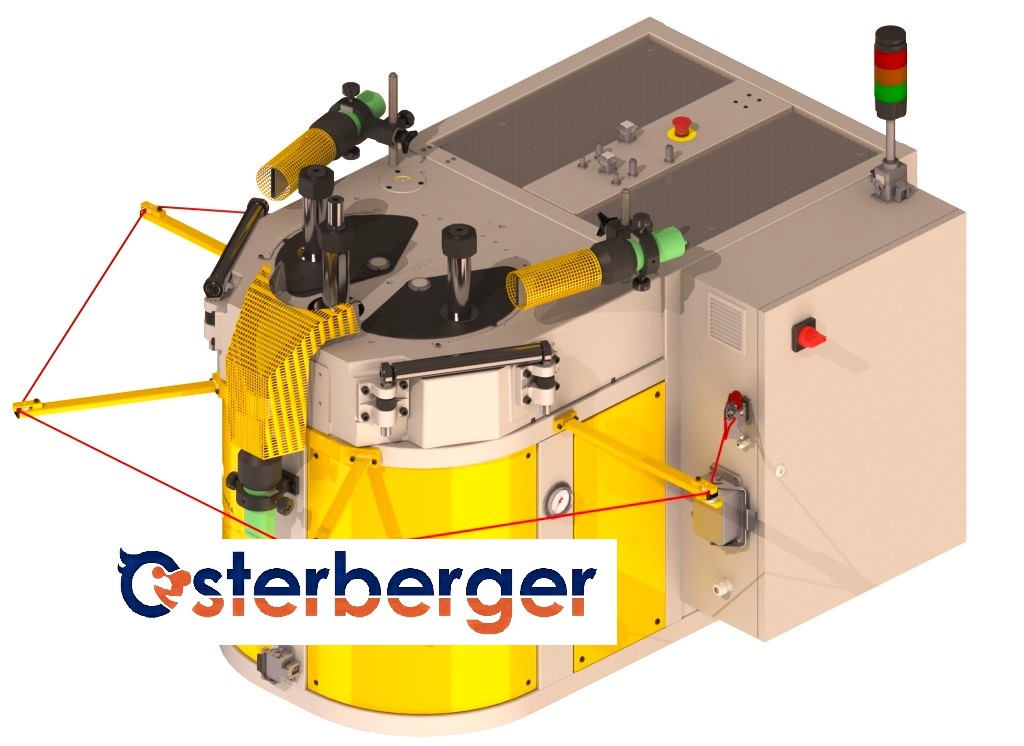

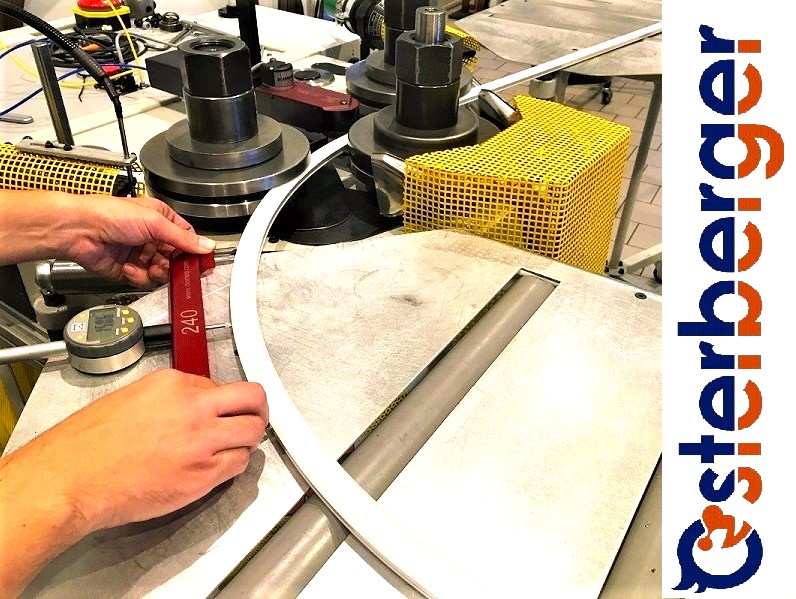

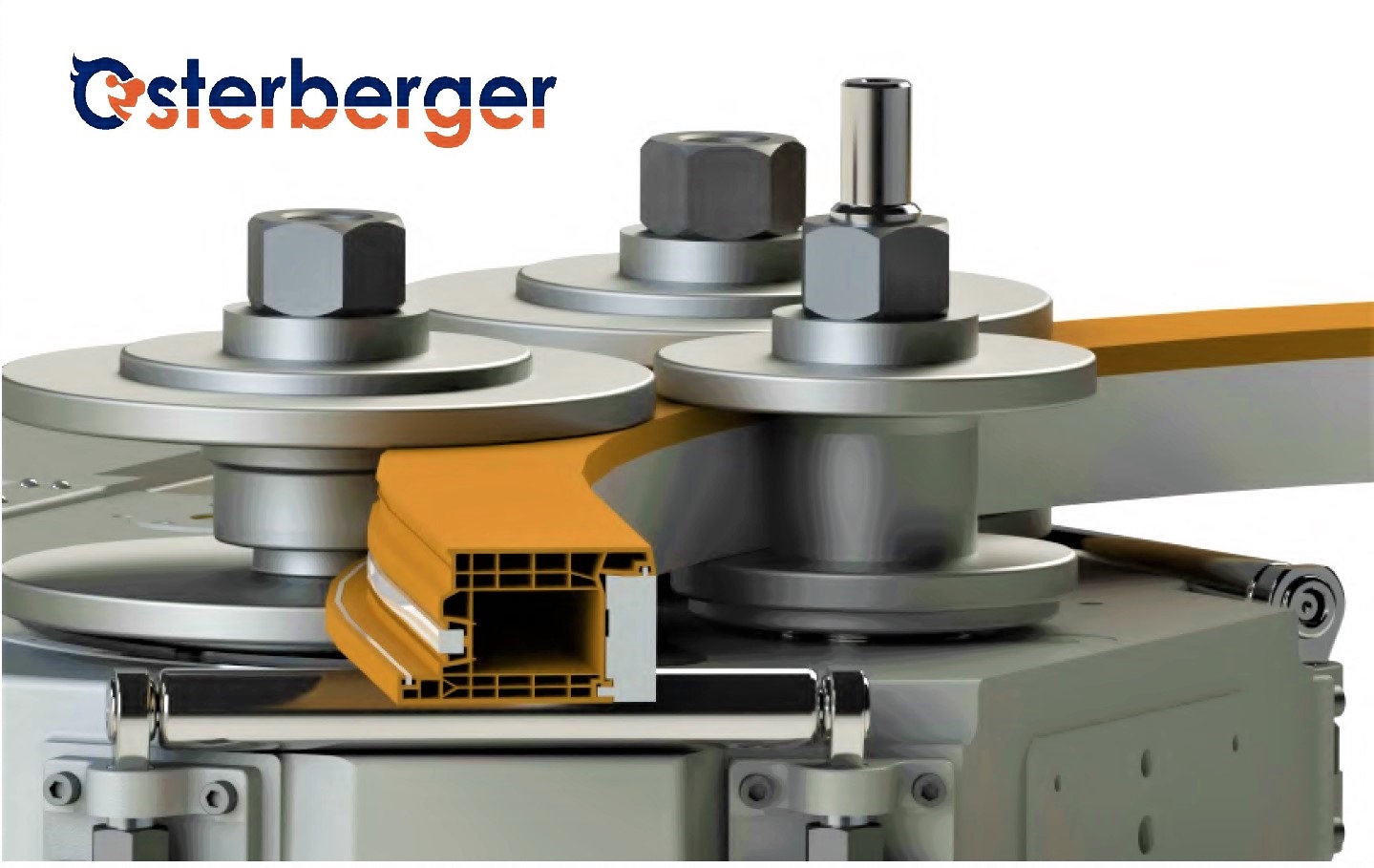

OSTERBERGER - REPANDUS - R70CNC.Ku - CNC - controlled profile bending machine for demanding and precise bending work with plastic profiles for window and door construction. Depending on the equipment, our machines can also be used for three-dimensional bending work. Our REPANDUS.Ku models work horizontally. The profile to be bent is clamped between the rollers and heated during the bending process; this heated profile is then bent as required.

|

The models in the OSTERBERGER - REPANDUS.Ku series work with a fixed top roller and two movable bottom rollers - this means that the straight end piece is relatively short compared to machine concepts with fixed bottom rollers. The machine body is made of vibration-damping cast steel, shaft diameter of the top and bottom rollers Ø 70 mm - shafts made of special steel - hardened and ground, bending force 190 kN - largest surmountable moment of resistance with standard rollers W = 35 cm³, smallest possible bending radius with standard rollers 120 mm, roller speeds 1 to 15.6 rpm, drive power roller drive 4 kW - drive power hydraulic unit 4 kW, weight approx. 1050 kg.

|

High-end CNC control system based on Windows® version 10 with TFT colour monitor and graphic product display. Our specialised software works with special algorithms for the control and regulation of three to five CNC axes in connection with profile and tube bending work. Automatic calculation of 150 roller speeds and 500 positioning speeds of the bottom rollers. Automatic work cycle, workpieces can be bent in one or more passes. Up to 36 different consecutive radii can be bent on one material bar.

|

|

|

|

|

|