|

|

Five Axis Sawing-, Drilling- and Milling Centre

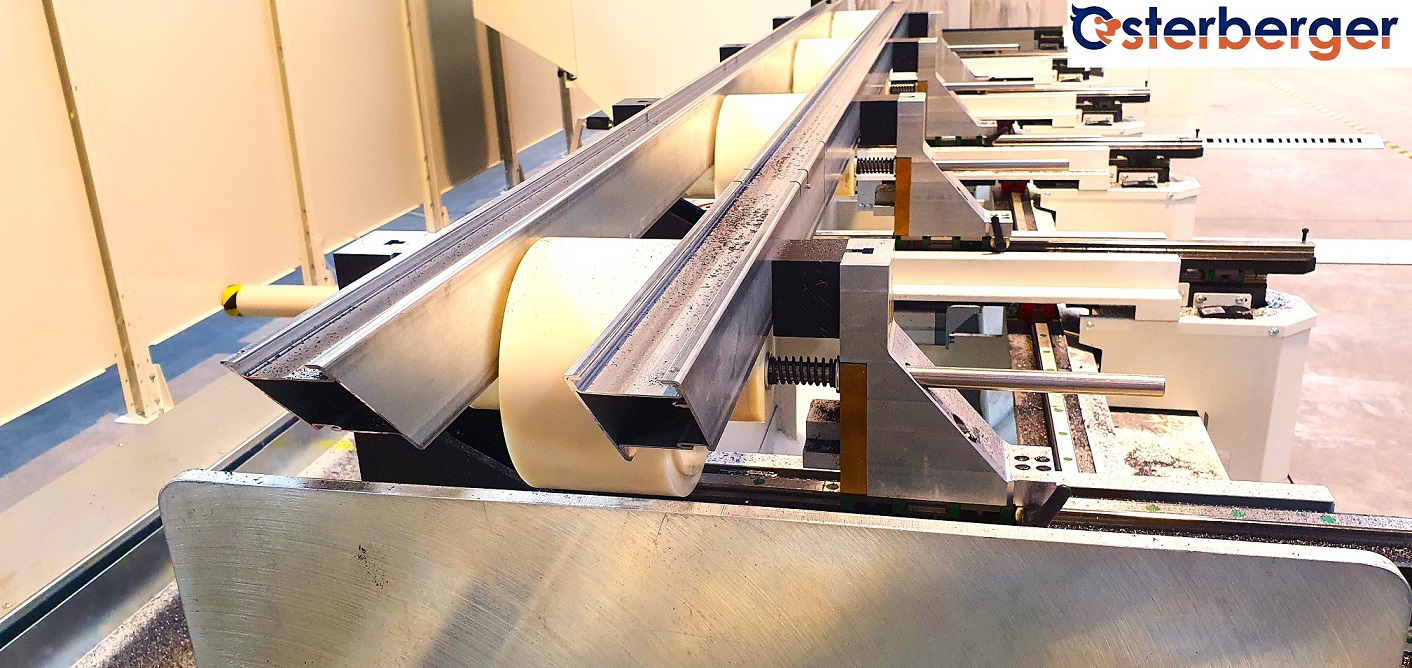

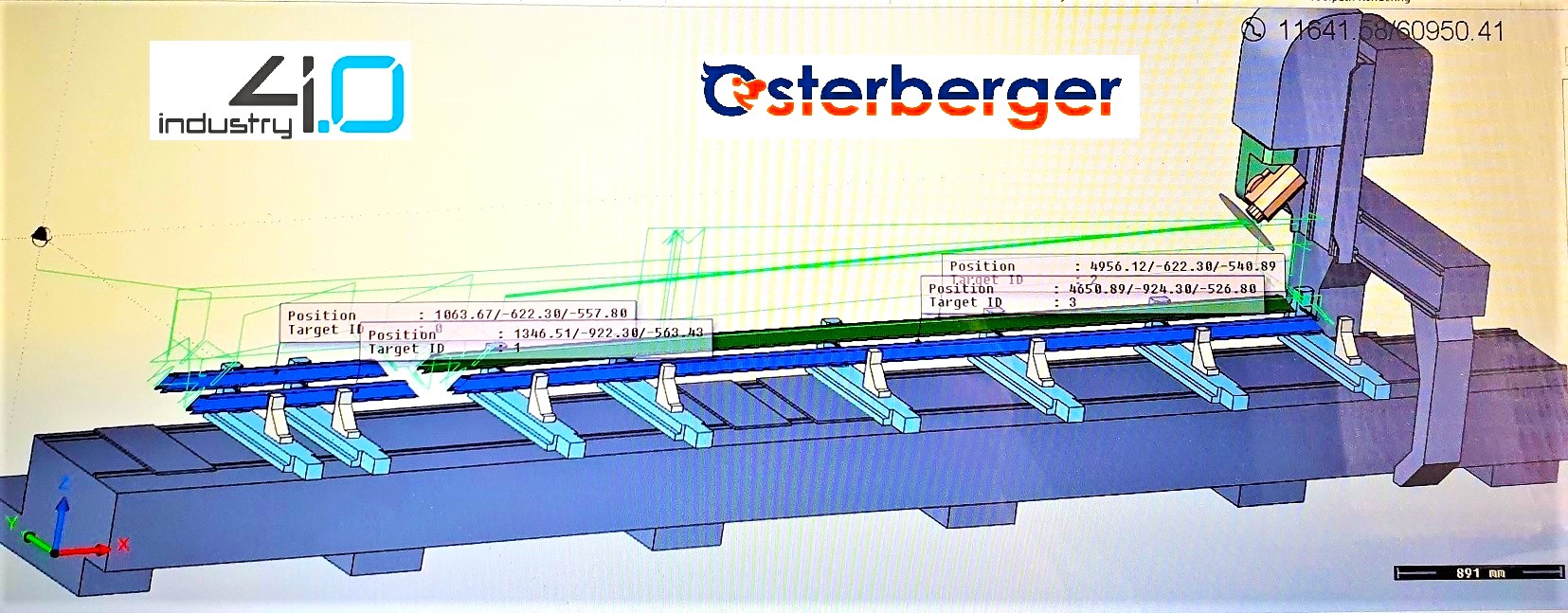

SBFZ5 - 5-axis sawing, drilling and milling - Portal machining centre with seven metre machining length (alternatively - 9 metre or 4 metre machining length) for all profile and tube materials - aluminium - steel - stainless steel - plastics - fibre-reinforced plastics such as GRP and CFRP Sawing with a diamond saw blade - sawing - drilling + tapping, flow drilling, milling + thread milling at a free angle - for example steel profiles sawing up to 15 mm wall thickness - glass or carbon fibre materials up to 25 mm wall thickness, largest saw blade diameter 500 mm, largest processing length with five-sided processing 7. 000 mm - largest workpiece cross-section 650 mm x H 450 mm, working area in five-axis operation 9,000 mm x 475 mm x H 450 mm, spindle drive power 18 kW at 60% ED - 15 kW at 100% ED - milling spindle speeds up to 24. 000 rpm, travelling turret tool magazine for 12 tools, HSK63 tool holder, rapid traverse speeds up to 100 m/min / acceleration 2.5 G, space requirement (including safety fence, control cabinet, light barriers and control panel) approx. 13 m x 5 m x H 2,7 m, basic machine weight approx. 4.500 kg. |

|

|

OSAI® five-axis CNC control, YASKAWA® feed drives and feed controllers, HITECO® milling spindle with ceramic bearings - liquid-cooled, 8 CNC-controlled motorised clamping bridges, remote control unit for infinitely variable control of the feed speeds and spindle speed, ball screws in the Y and Z axes, CAD/CAM software with 3D colour graphics - the software allows simultaneous machining of two profile bars side by side, import and generation of DXF files, 3D simultaneous display of the machining programs in colour, remote maintenance of the machine, chip conveyor belt, air-conditioned switch cabinet, minimum quantity cooling lubrication, central lubrication system for the guideways, automatic tool length measurement.

|

|

|

|

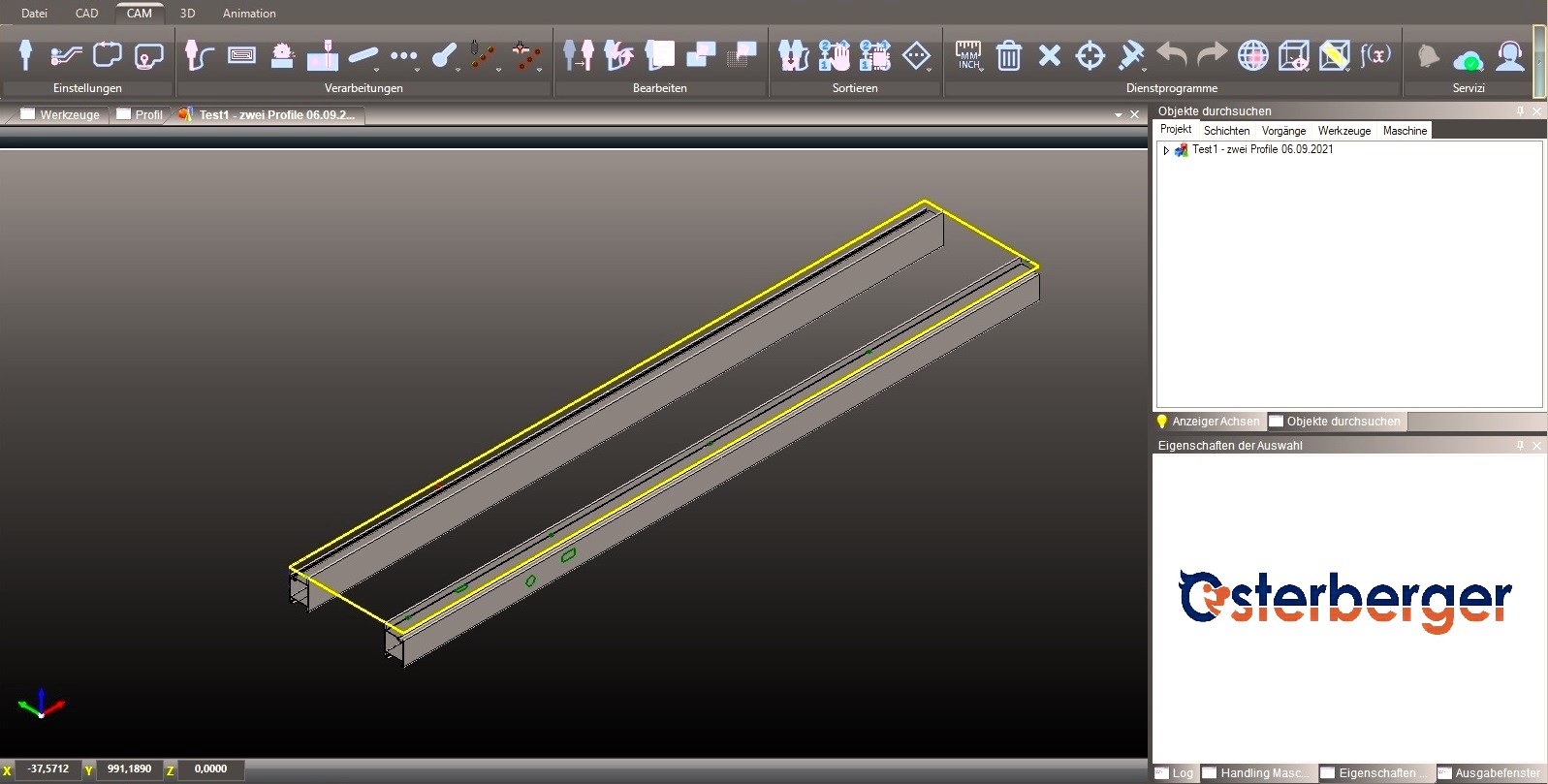

Edit two profiles at the some time

Our software is able to calculate and control different machining operations on two profiles in one clamping. This special feature increases the productivity of our SBFZ5 machining centres by 100% compared to similar machines, but also means less non-productive time and less work to load the machines with raw material. |

|

|

Finishing two profiles simultaneously on five sides in one clamping operation, sawing - drilling - tapping - milling, not everyone can do that. A decision in favour of our machine means maximum productivity and maximum precision for the user. |

|

|

100% designed and built in EUROPA

90% built from European components* for efficient, environmentally friendly production of the highest quality. *European components mean short transport routes, very high quality and extensive availability. |

|

|

|

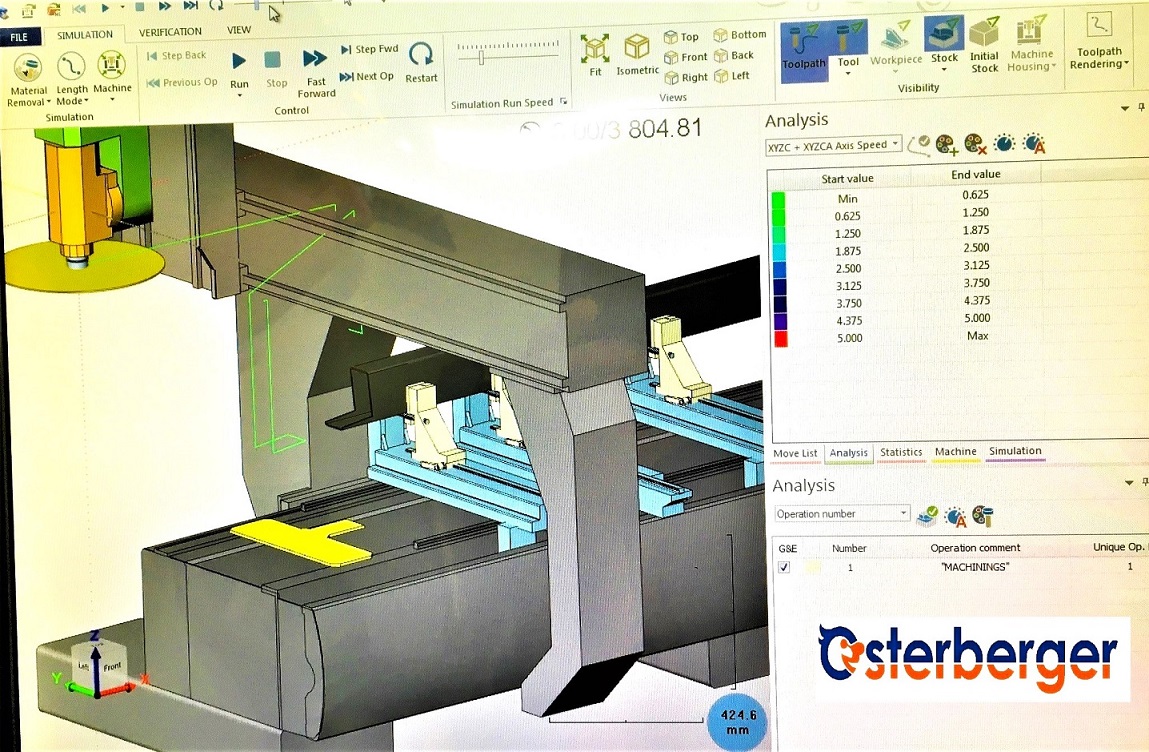

Our Software fulfils all wishes

Simple and fast workpiece programming in the office or directly at the machine, fast and uncomplicated programming and management of tools. Two software modules allow simultaneous machining with three-dimensional display in colour; any programming errors can be detected and corrected immediately during simultaneous machining.

|

|

|

|

MADE IN EU - also means short transport routes. The systems, equipment, machines and devices we offer do not have to be transported thousands of kilometres by sea. Everyone talks about environmental protection and resource conservation, we act accordingly and pay attention to sustainability. We make sure that the systems, equipment, machines and devices we sell are manufactured with the lowest possible environmental impact and the greatest possible conservation of resources. |