|

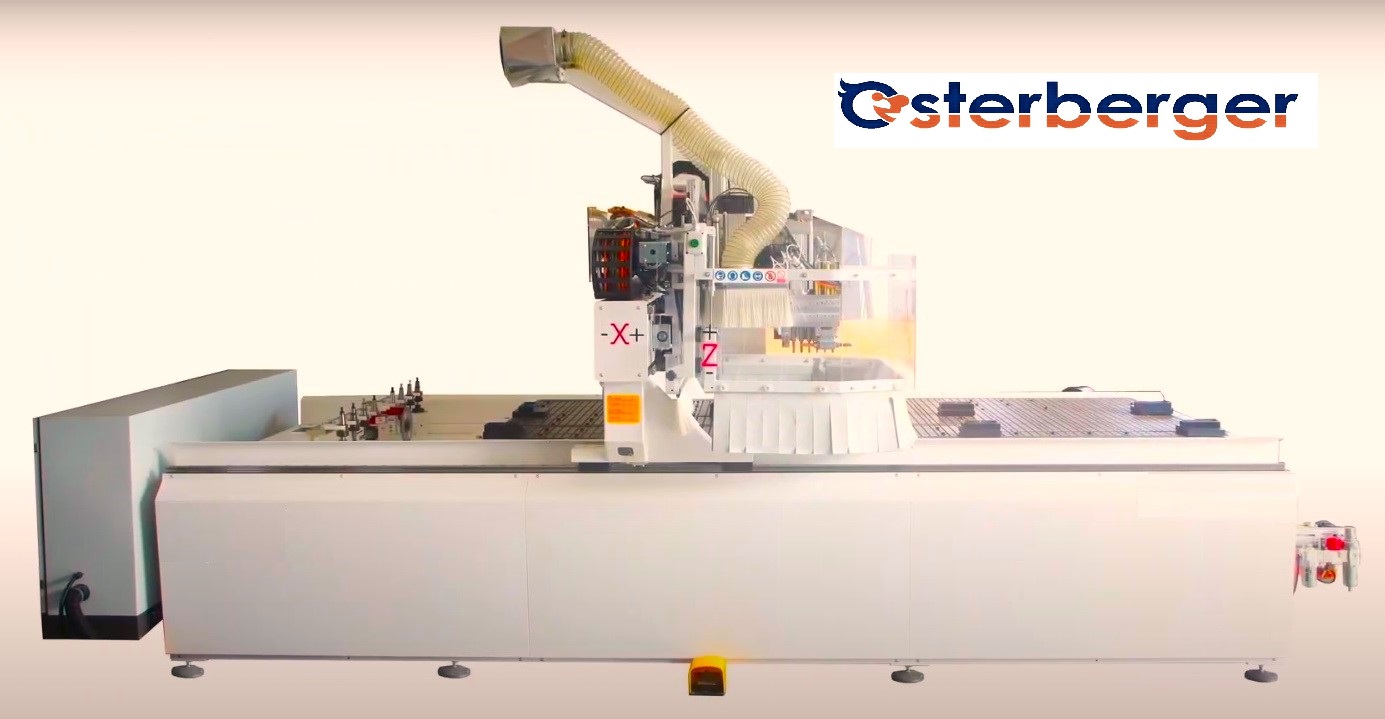

OSTERBERGER PLANUS flatbed plate and panel processing centre

|

OSTERBERGER PLANUS flatbed panel processing centre - equipped with three, four or five CNC axes. These CNC machines are suitable for processing solid wood panels - HPL - laminate panels such as FUNDERMAX® - pressboard - MDF panels - plastic panels (e.g. PVC / PE) - synthetic resin panels and other boards and panels which can be clamped by vacuum.

|

The PLANUS series machines are available with two different clamping options - in version one, the material is clamped by vacuum on a synthetic resin plate; in version two, the material is also clamped by vacuum, but the suction blocks are located on clamping bridges that can be moved in length.

|

Drilling - milling - sawing, all with one machine. The machines can be configured according to the customer's requirements. Milling spindle drive power 11kW to 18 kW - Tool holder in the SK30/SK40 or HSK40/HSK63 milling spindle - Milling spindle speeds up to 24,000 rpm. The machines are equipped as standard with a travelling turret tool magazine for 8 tools. In addition, the machines can be equipped with ‘pick-up’ tool magazines at the machine ends, so that up to 48 tools are available. An additional drilling and routing unit with 1.7 kW drive power that can be swivelled by +/- 45° is also available.

|

In addition to the main milling spindle, the machines can be equipped with multi-spindle drilling units, for example with drilling heads with up to thirty-five spindles. Various sawing units are available for sawing operations. A 90° swivelling ‘GROOVE’ unit is also available for milling operations with disc cutters.

|

Working area 3,000 mm x 1,300 mm or 4,100 mm x 1,600 mm, maximum panel height 80 mm. Dimensions 4.15 m / 5.25 m x 2.15 m / 2.45 m x H 2 m / 2.25 m, weight 3,000 / 3,800 kg.

|

|