|

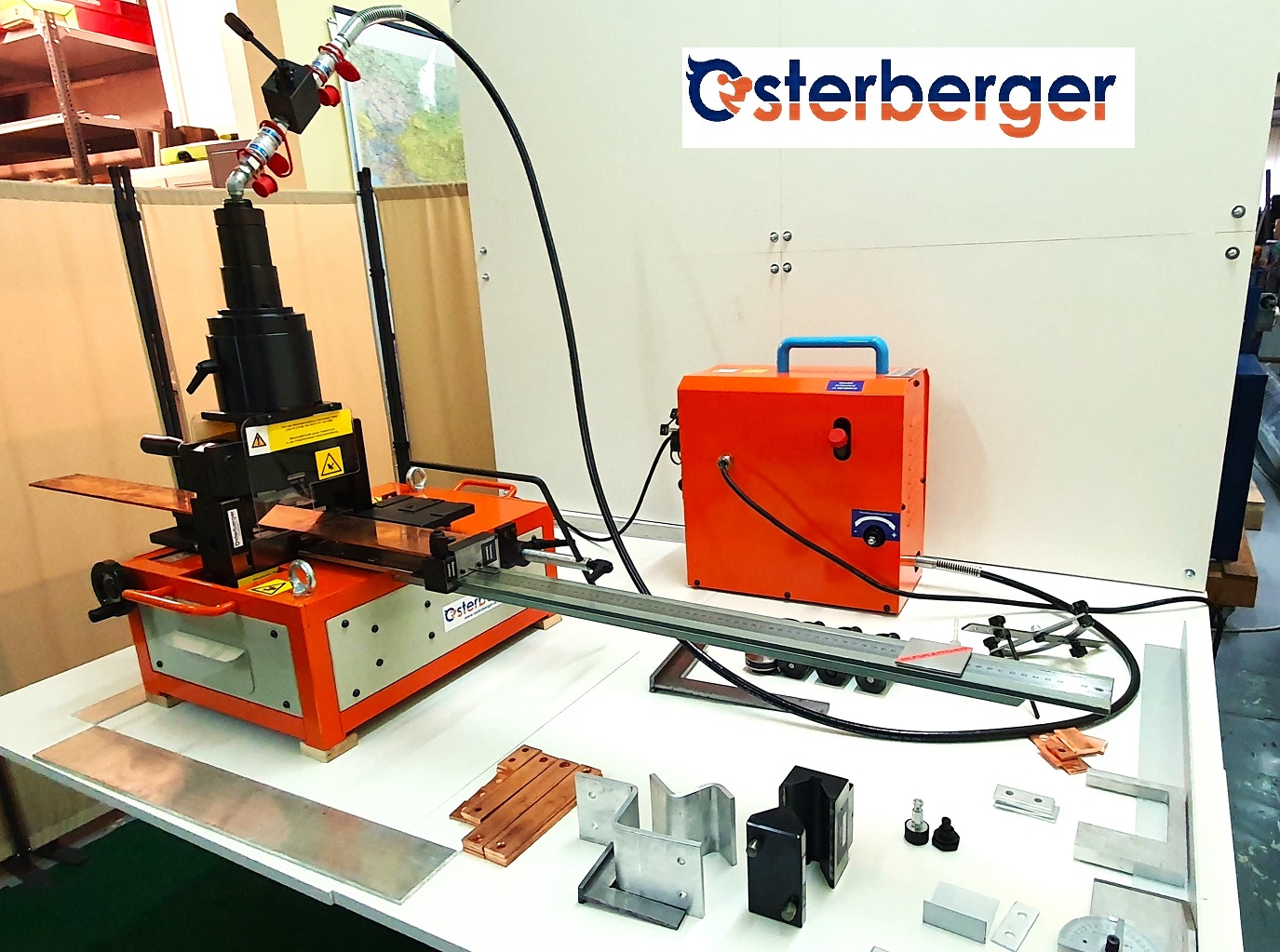

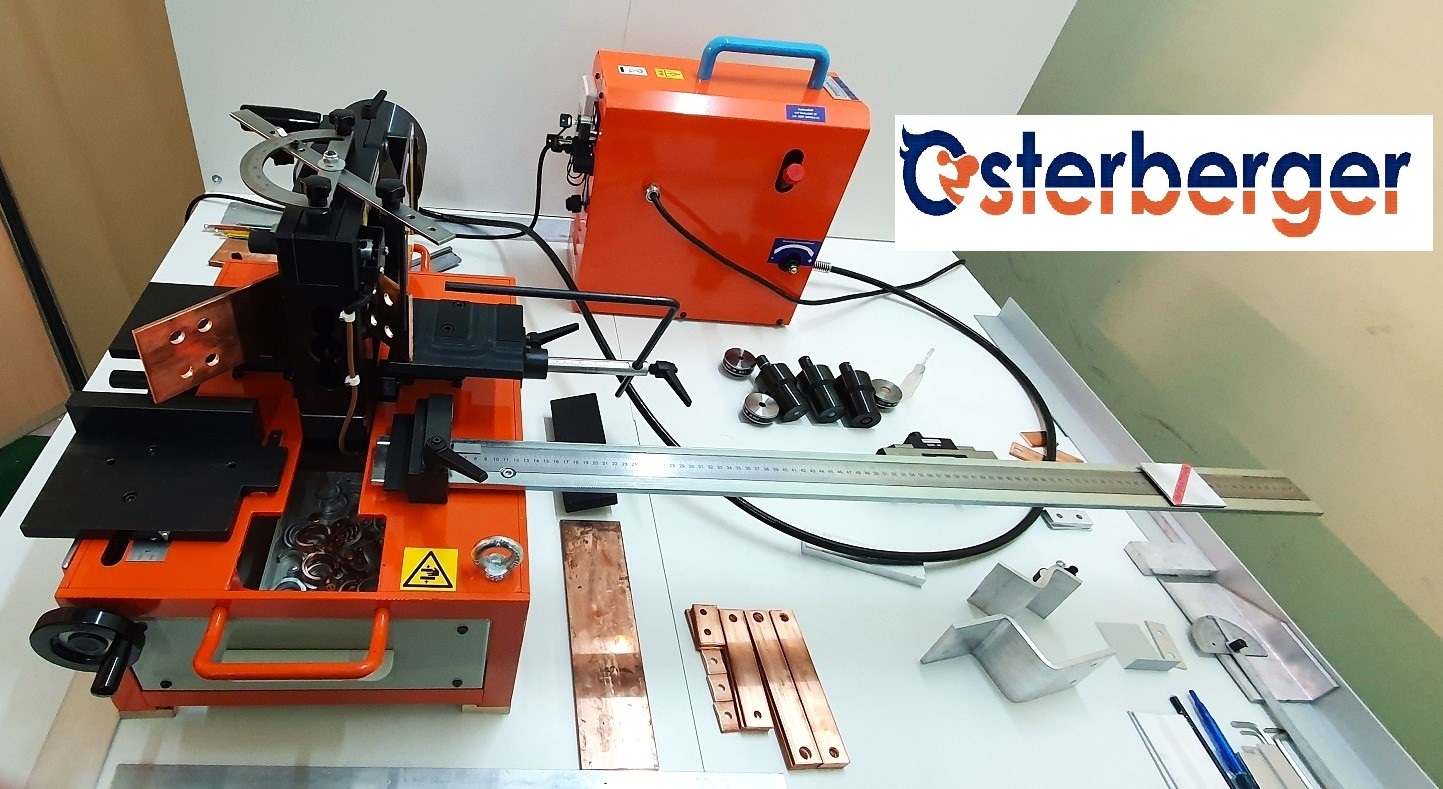

SPU200/300 - multifunctional machining centre for copper bars / flat copper material

punching + pressing - universally applicable - cutting to length - hole punching - bending + folding

|

Only a few tools are required for exact cutting, precise punching, and accurate bending. A single machine is all that is needed to complete many tasks quickly and efficiently "around the copper rail" in manual switch cabinet construction.

|

SPU200/300 - multifunctional hydraulic press - many things can be done with just one machine - shearing/cutting (cutting the material bar to the desired length) - punching (round hole / slotted hole / square + rectangle) - bending to the desired angle (folding). The materials copper - aluminium - COPPAL® composite material - brass and other "soft" materials can be processed. Maximum pressing force 200 kN - optional 300 kN, maximum material thickness in copper up to 12 mm - optional at 300 kN up to 15 mm, maximum material width in copper up to 120 mm - optional at 300 kN up to 160 mm, maximum punching diameter with standard tools Ø 25 mm - with special tools Ø 50 mm.

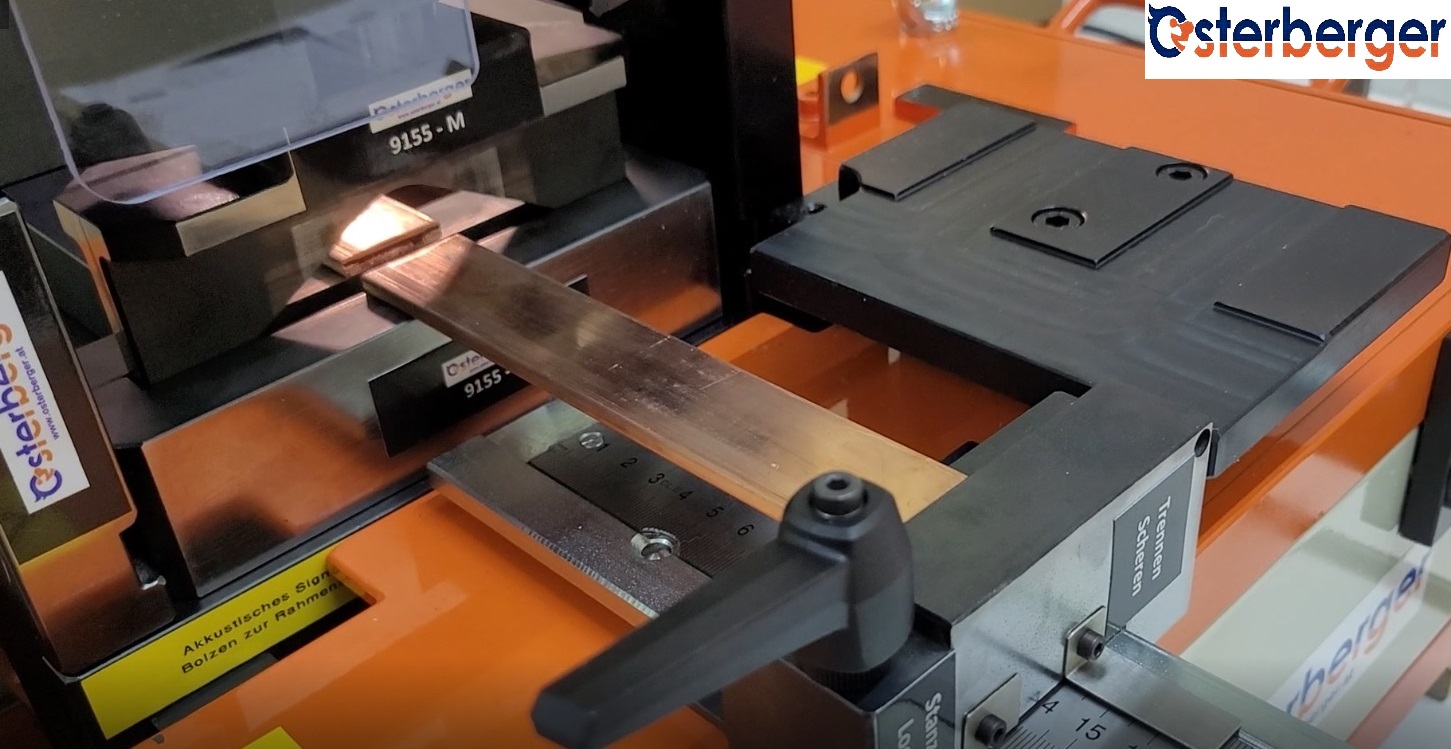

SPU200/300 - the shear cut - precise cutting to the desired length

|

Flat material, copper - aluminium - COPPAL® composite material - brass and other "soft" materials are cut to length using a shear cut. The shearing unit consists of the upper blade and the lower blade. The material to be cut to length is placed on the shearing table and the stop slide. Two precision fences enable precise fences and, as a result, exact, dimensionally accurate cutting. Very short cuts are also possible, shortest cut 58 mm when using the stop pusher on the support ruler, when using the stop bracket the shortest cut is approx. 20 mm.

|

|

The material to be cut is placed on the shearing table, on the lower blade and on the stop pusher. Longer sections are placed on the pusher stop; shorter sections are placed on the stop bracket. The fence dimensions can be read off the length scale and the width scale.

|

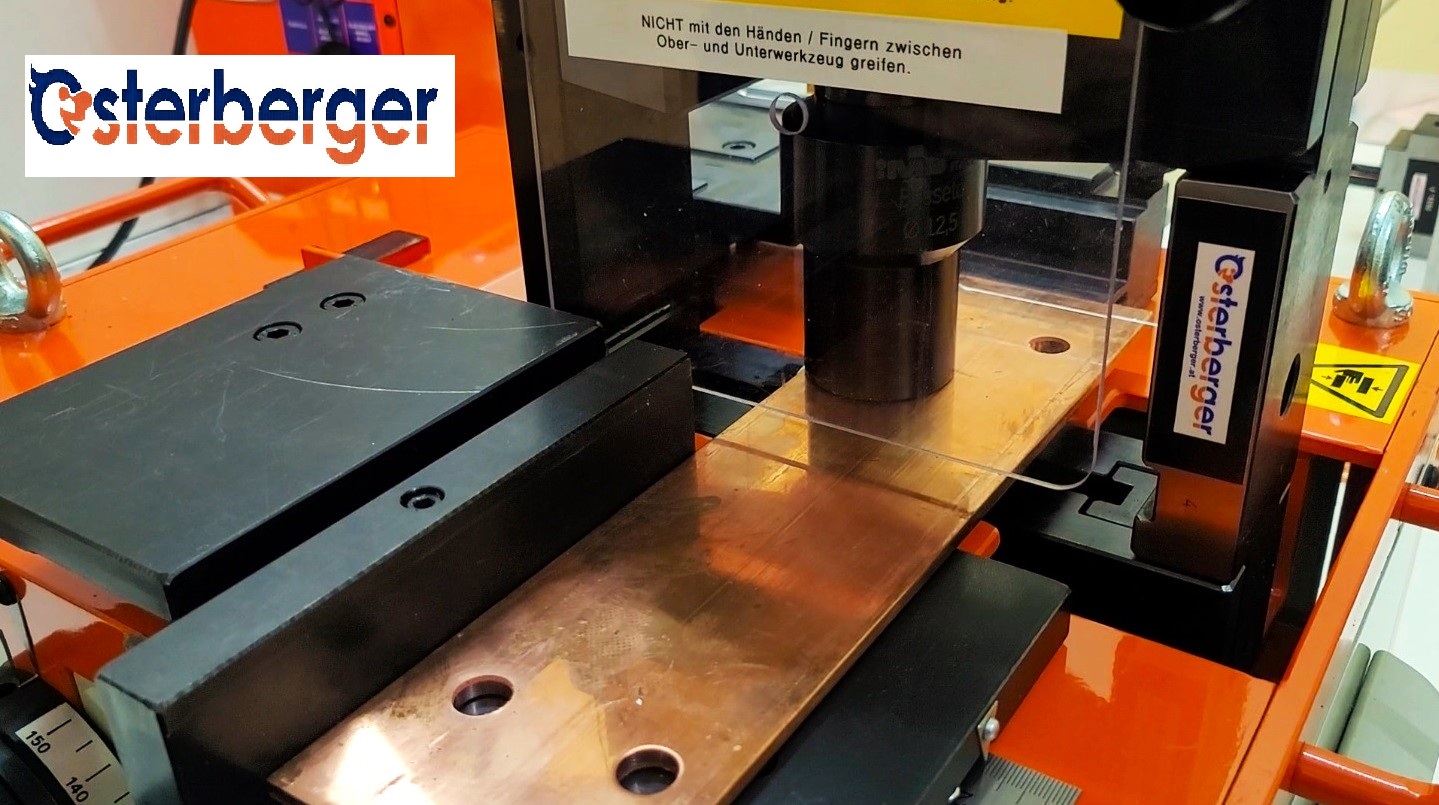

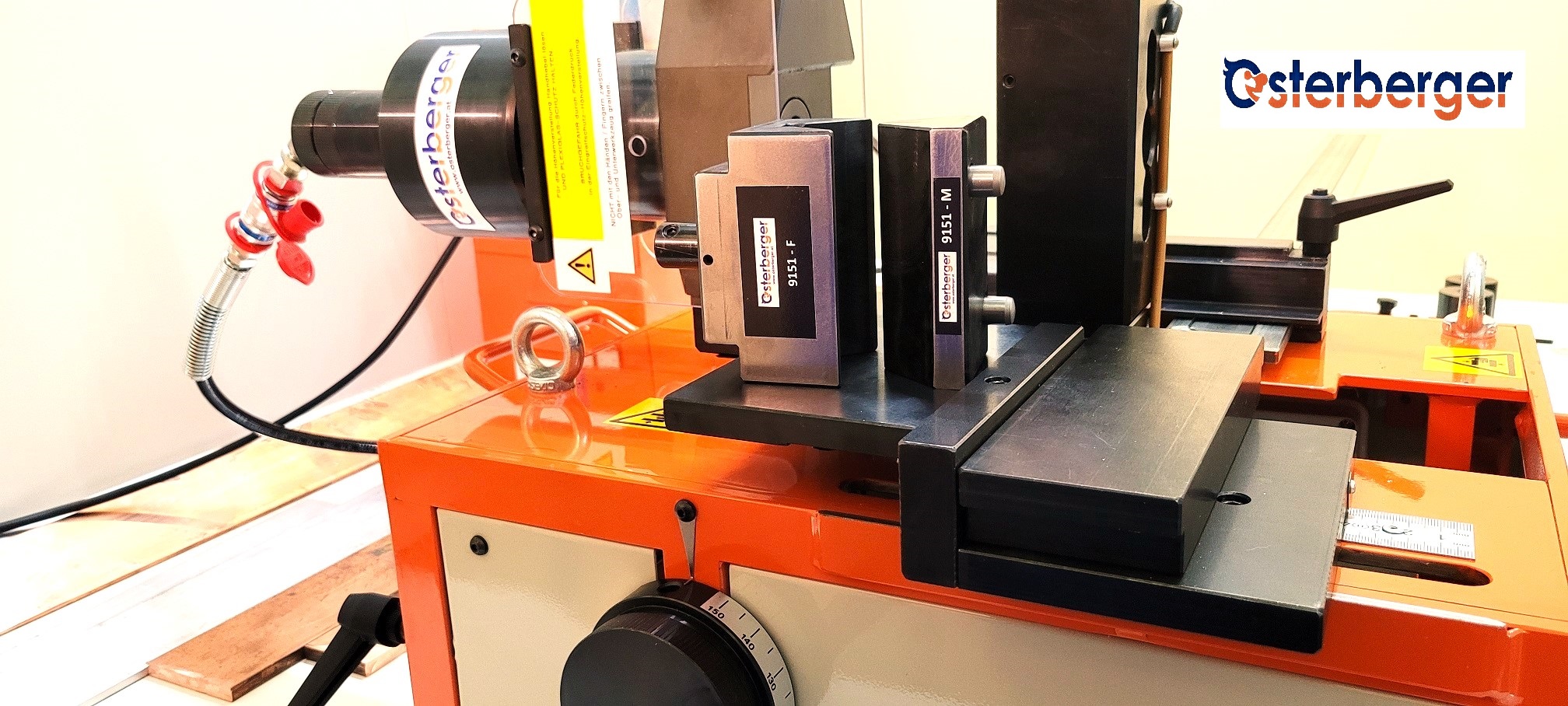

SPU200/300 - Punching + perforating - simple, precise, and fast

|

The changeover time from shearing to punching is approximately one minute. With hole punching, the material bar is also placed on a support table. The support table can be adjusted using a hand crank and serves as a width stop, making it possible to position the material for punching exactly in width. The positioning in length is done in a similar way to shearing by pressing the material bar against the stop slider.

|

100% designed and built in EUROPE

made from very high-quality European components

|

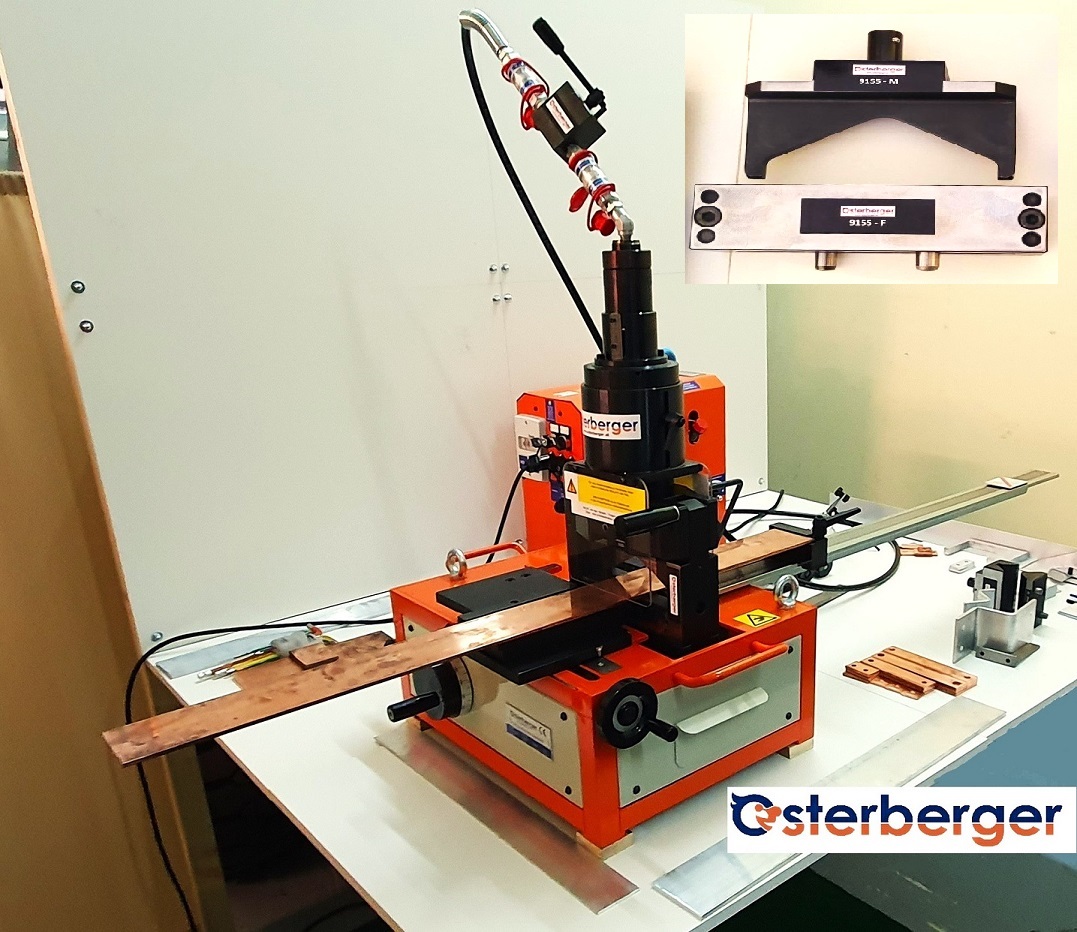

SPU200/300 - Bending - precise bending to the desired bending angle

|

|

But our SPU200 can not only perform shear cuts and punch holes, with the bending device any flat material made of copper - aluminium - COPPAL® composite material - brass and other "soft" materials can be bent or folded. Folding width / bending width with standard tools up to 120 mm - with special tools up to 160 mm - optionally with the machine with 300 kN press force up to 200 x 20 mm.

|

The changeover time from shearing / punching to bending / folding is also only around one minute. Our precision immersion depth limitation enables repeatable, exact bending up to a bending angle of approx. 105°.

|

Thanks to our well-thought-out design, which has proven itself in practice, several bends can be carried out on one workpiece, one material bar, without colliding with the machine frame.

|

Precise adjustment of the immersion depth of the hydraulic piston is guaranteed with our design