|

|

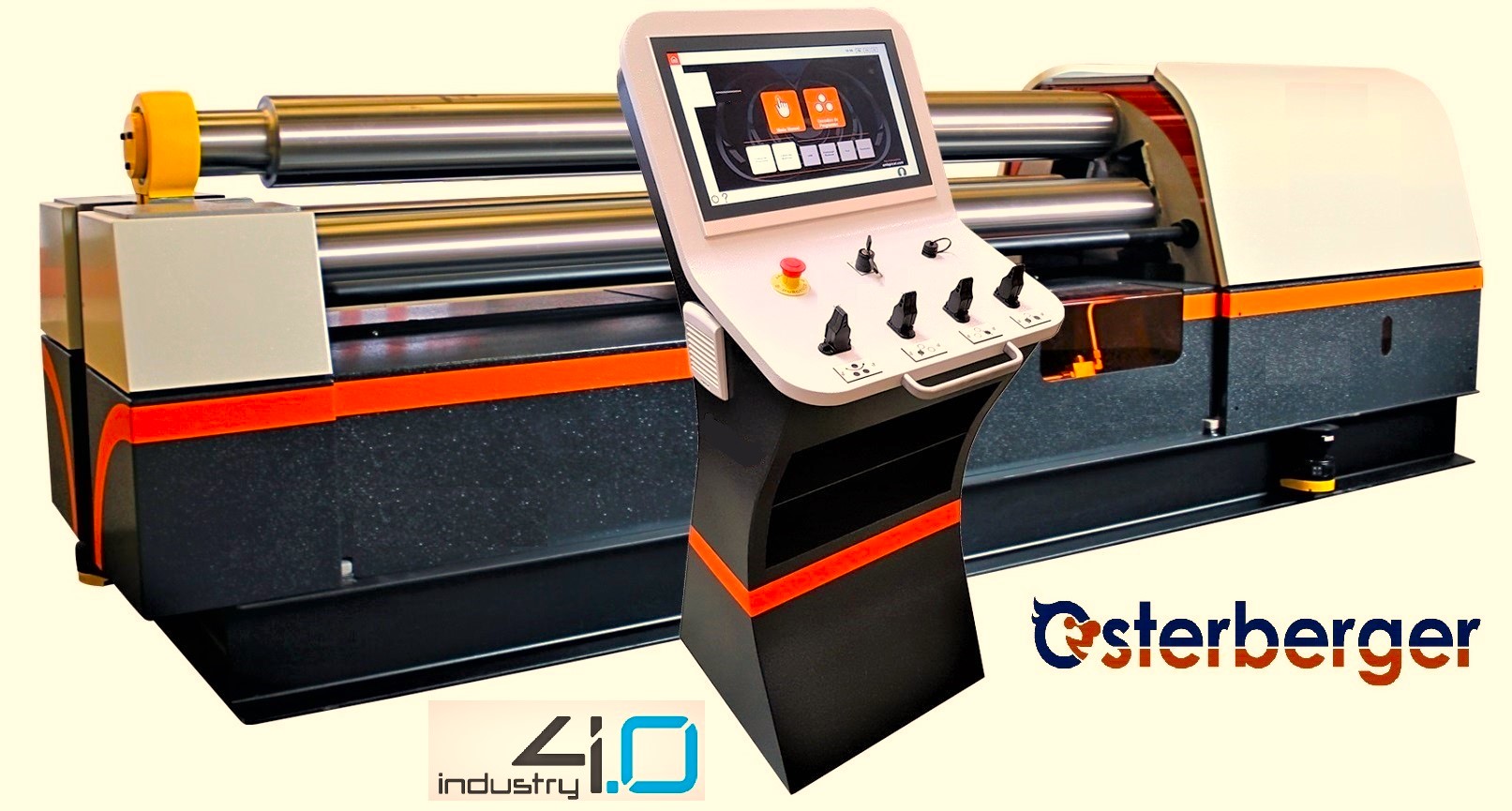

ADJUNCTUM

ADJUNCTUM - fully hydraulic plate roll bending machines with patented servo-hydraulic valve control. ADJUNCTUM sheet metal roll bending machines are premium class hydraulic machines. ADJUNCTUM sheet metal roll bending machines combine the highest possible quality with dynamics and precision.

|

|

|

100% designed and built in EUROPA

90% built from European components* for efficient, environmentally friendly production of the highest quality. *European components mean short transport routes, very high quality and extensive availability.

|

|

|

ADJUNCTUM4 - 3100/235 - fully hydraulic sheet metal roll bending machine (round bending machine) with four rollers and patented servo hydraulics, all four rollers are independently hydraulically driven by oil motors - special control of the clamping roller (electronic monitoring of position and clamping pressure). The machine is suitable for the roll bending of sheets from 2,5 mm sheet thickness, maximum nominal pre-bending capacity for steel sheets with a tensile strength of approx. 240N/mm² = 8 mm with a bending length of 3.050 mm and a sheet shot inside diameter of Ø 1.175 mm, diameter of the bending rolls 235 mm - smallest possible bendable inside diameter 305,5 mm - the rolls run in slide bearings - linear feed of the bottom rolls directly by hydraulic cylinders with very large dimensioned piston rods. The standard equipment includes a conical bending device - hardened and ground rollers made of special steel - 50/60 HRC hardness - central lubrication system, drive power 7,5 kW, weight approx. 5.750 kg.

|

|

|

ADJUNCTUM3 - 3100/205 - fully hydraulic sheet metal roll bending machine (round bending machine) with three bending rolls and patented servo-hydraulics, all three rolls are independently hydraulically driven by oil motors. The machine is suitable for roll bending sheet metal from 1 mm or 2 mm sheet thickness, maximum nominal pre-bending capacity for steel sheets with a tensile strength of approx. 240N/mm² = 6 mm with a bending length of 3,050 mm and an inner sheet diameter of Ø 1.025 mm, diameter of the rolls 205 mm - smallest possible bendable inner diameter 225,5 mm - the rolls run in slide bearings - linear feed of the lower rolls directly by hydraulic cylinders with very large piston rods. The standard equipment includes a conical bending device - hardened and ground rollers made of special steel - 50/60 HRC hardness - central lubrication system, drive power 5,5 kW, weight approx. 3.700 kg.

|

|

|

ADJUNCTUM3 - 2100/170 - fully hydraulic plate bending machine with three bending rolls and patented servo-hydraulics, all three rolls are independently hydraulically driven by oil motors. The machine is suitable for the roll bending of sheets from 1 mm or 2 mm sheet thickness, maximum nominal pre-bending capacity for steel sheets with a tensile strength of approx. 240N/mm² = 5 mm with a bending length of 2.050 mm and a sheet shot inside diameter of Ø 850 mm, diameter of the rolls 170 mm - smallest possible bendable inside diameter 187 mm - the rolls run in slide bearings - linear feed of the bottom rolls directly by hydraulic cylinders with very large dimensioned piston rods. The standard equipment includes a conical bending device - hardened and ground rollers made of special steel - 50/60 HRC hardness - central lubrication system, drive power 4 kW, weight approx. 2.900 kg. |

|

|

ADJUNCTUM3 - 1500/115 - fully hydraulic sheet metal roll bending machine with three bending rolls and patented servo-hydraulics, specially developed for thin sheet metal processing, all three rolls are independently hydraulically driven by oil motors. The machine is suitable for the roll bending of sheets from 0,5 mm sheet thickness, maximum nominal pre-bending capacity for steel sheets with a tensile strength of approx. 240N/mm² = 2.5 mm with a bending length of 1.550 mm and a sheet shot inside diameter of Ø 575 mm, diameter of the rolls 115 mm - smallest possible bendable inside diameter 126,5 mm - the rolls run in slide bearings - linear feed of the bottom rolls directly by hydraulic cylinders with very large dimensioned piston rods. The standard equipment includes a conical bending device - hardened and ground rollers made of special steel - 50/60 HRC hardness - central lubrication system, drive power 2,2 kW, weight approx. 1.500 kg. |

|

|

MADE IN EU - also means short transport routes. The systems, equipment, machines and devices we offer do not have to be transported thousands of kilometres by sea. Everyone talks about environmental protection and resource conservation, we act accordingly and pay attention to sustainability. We make sure that the systems, equipment, machines and devices we sell are manufactured with the lowest possible environmental impact and the greatest possible conservation of resources. |